1 With intelligent adjustment and automatic operation function.

2. With the single-chip rejection function,

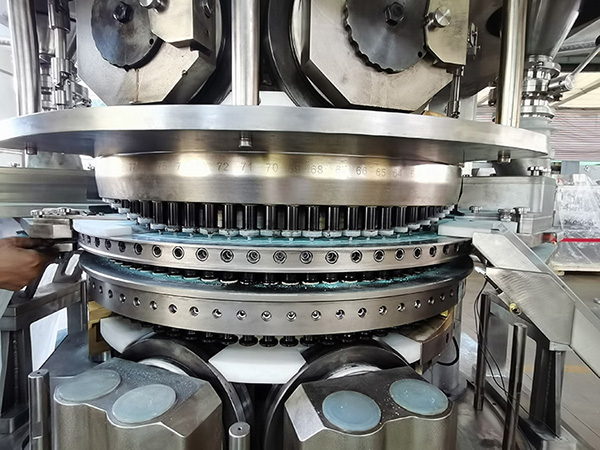

3. Modular design, in which the turntable module and the upper and lower rail modules can be disassembled online. The main pressure adjustment module and the pre-pressure adjustment module are interchangeable.

4. Comply with GMP requirements,.

5. Pressure detection system upgrade.

6.The output force pressure sensor is placed under the film output guide to directly detect the output force.

electroplated with hardened chromium to improve the wear resistance.

7.Using an intelligent central lubrication system to ensure that each lubrication point is fully lubricated.

High speed | GZP51/2 | GZP63/2 | GZP75/2 | GZP81/2 |

Dies(pair) | 51 | 63 | 75 | 81 |

Dies Model | D | B | BB | BBS |

Capacity | MIN | pcs/Hour | 91800 | 113400 | 135000 | 145800 |

MAX | pcs/Hour | 440640 | 544320 | 648000 | 777600 |

Max. force(KN) | kN | 100 | 100 | 100 | 100* |

Max. tablet diameter | mm | 25 | 16 | 13 | 11 |

Max. filling depth | mm | 22 | 18 | 18 | 18 |

Max. tablet thickness | mm | 8.5 | 8.5 | 8.5 | 8.5 |

Speed | r/min | 15-72 | 15-72 | 15-72 | 15-80 |

Middle Die Diameter | mm | 38.1 | 30.16 | 24 | 22 |

Middle Die height | mm | 23.8 | 22.22 | 22.22 | 22.22 |

Punch diameter | mm | 25.35 | 19 | 19 | 19 |

Upper punch length | mm | 133.6 | 133.6 | 133.6 | 133.6 |

Lower punch length | mm | 133.6 | 133.6 | 133.6 | 133.6 |

Upper punching depth | mm | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 |